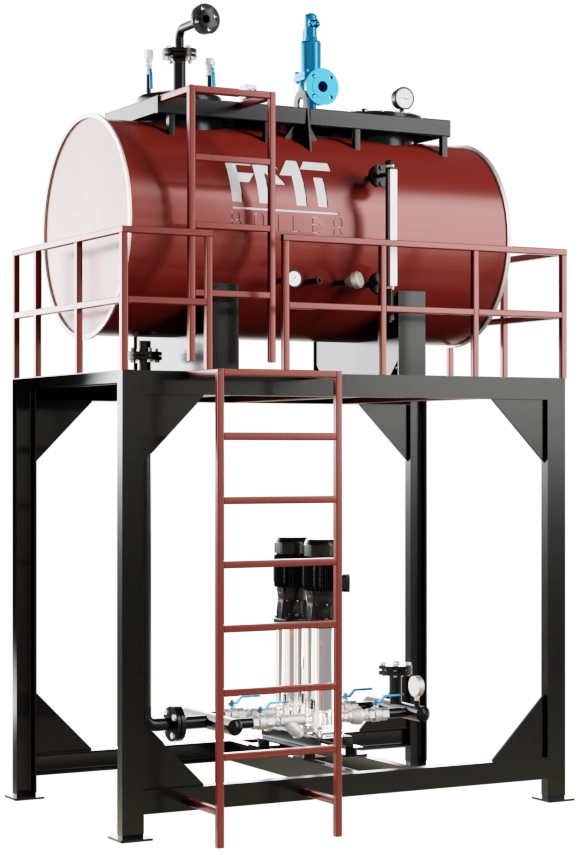

The primary causes of corrosion in steam boilers and piping systems are oxygen and carbon dioxide gases. The concentration of these gases in the water varies depending on the temperature. The higher the temperature, the more the gases are released from the water. To completely remove carbon dioxide from the water, a temperature of around 65°C is required, while for oxygen, this process occurs at 102°C. Once separated, the gases are discharged from the top of the deaerator dome. Consequently, the operating temperature of deaerators reaches up to 105°C, but high water temperatures can cause cavitation in the feedwater pump.

To prevent cavitation, the deaerator system is elevated above ground level to create positive pressure in front of the pump. For this purpose, a platform is designed with welded and bolted construction, with its static load calculated according to the required weight. The design includes a sailor-type ladder to reach and operate the valves on the deaerator tower and the lower deaerator tank, ensuring complete access and control.