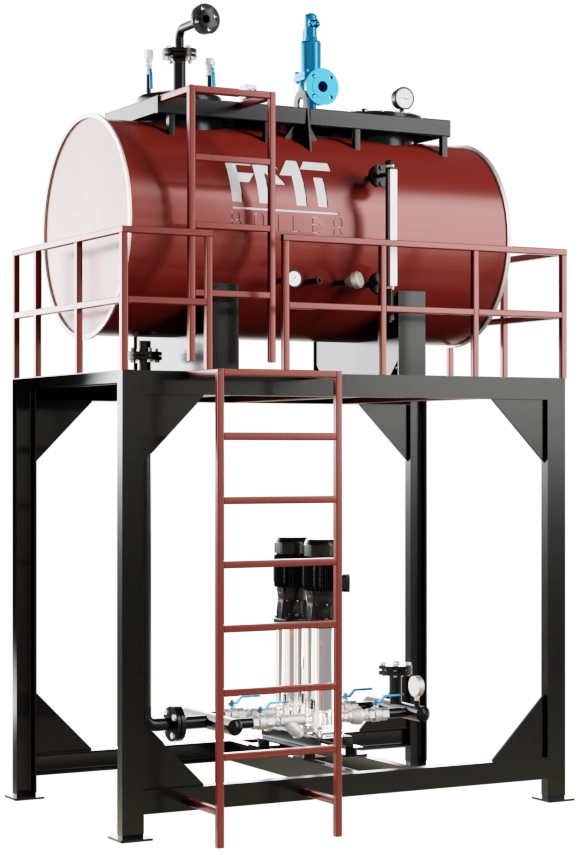

In steam production systems, dissolved oxygen and carbon dioxide in the feedwater are highly corrosive gases that can negatively affect the long-term durability and efficiency of the system. To prevent these gases from entering the steam generator and causing corrosion, they need to be removed from the water and rendered harmless. Carbon dioxide is fully separated from the water at 65°C, while oxygen is fully separated at 102°C. The separated gases are vented through the top of the deaerator dome and discharged from the system.

Thermal deaerators operate at a working temperature of 105°C. To prevent cavitation in the feedwater pump at this temperature, the deaerator must be positioned approximately 5 meters above ground level. This elevation creates positive pressure at the pump inlet, thereby preventing cavitation.